The quality of the slewing bearing raceway processing is very important for the slew bearing load capacity and service life. If the raceway processing of the slewing bearings is not good, even if the surface inspection is qualified, the service life of the slew bearings is generally very short, maybe half a month, Maybe 2 months.

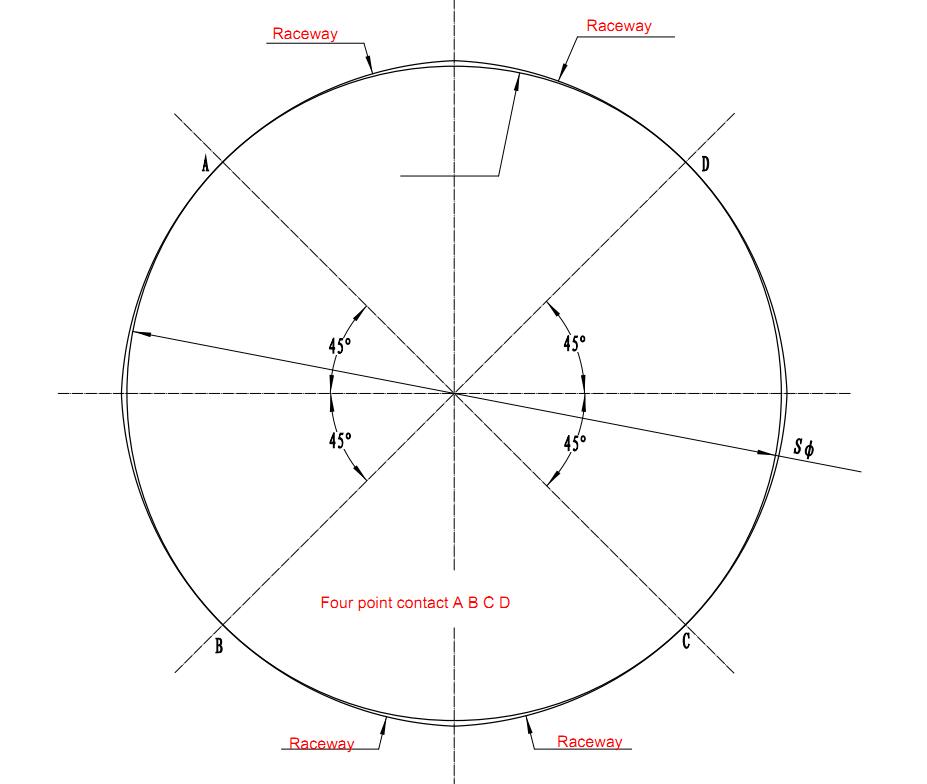

Therefore, the processing technology of the slewing bearing raceway directly affects the quality of the slew bearings, and it is also the most important factor in determining the quality of the product. After a long time of trial and theoretical research by our company's technical department and production department, we have formulated the leading slewing bearing raceway contact point angle processing technology in the slewing bearing industry, which has made our slewing bearing quality a qualitative leap. The slewing bearing standard requires the contact angle of the ball and the raceway to be 45 degrees.

The excellent domestic counterparts can only achieve 45 degrees +-6, and most of them can only achieve 45+-8, but after our company's special process standards Control, we can ensure that the contact angle is 45°±3. At the same time, in order to ensure the accuracy of the contact angle, we purchased 2 new raceway grinding machines to finish the processing of the raceway contact angle to all OEM products and export products, which ensures the stability of our product quality.