SWBTEC quality has two quality certified and recognized, one is ISO9001: 2008, the other is our internal quality control system.

SWBTEC select the best forging steel manufacturer- Masteel in China. Inspection are carried out at each step of manufacturing.

Most customer select 50Mn, 42CrMo, S48C,

Material | C | Si | Mn | S | P | Cr | Ni | Cu |

50Mn | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 | ≤0.25 |

Material | C | Si | Mn | S | P | Cr | Ni | Mo |

42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 | ≤0.30 | 0.15-0.25 |

Steel Ball and rollers: Balls and rollers are important to slewing ring, they have strong influence to the product life, SWBTEC balls and rollers quality has been proved for several decades.

Seal: The seal we choice is anti-corrosion and tensile resistance

Grease Oil: we only use the famous brand: Exxon Mobil Grease

Hardening Treatment: Quenched and Tempered are carried out to each piece with HB207-269.we do hardening treatment to the gear as customer requirement with HRC52±4 and HRC55-61 to raceway.

Product assembly inspection is the last and most important step before the product leaves our factory. It must ensure that the slew bearings is qualified before leaving the factory. For this reason, our company has arranged 5 inspectors in the last step. The main inspection contents include dimension, material matrix hardness, tooth quenching hardness, raceway quenching hardness, axial & radial clearance, face runout, maximum point of tooth runout, ball loading quantity, the surface of the product is free from cracks and scratches,etc.

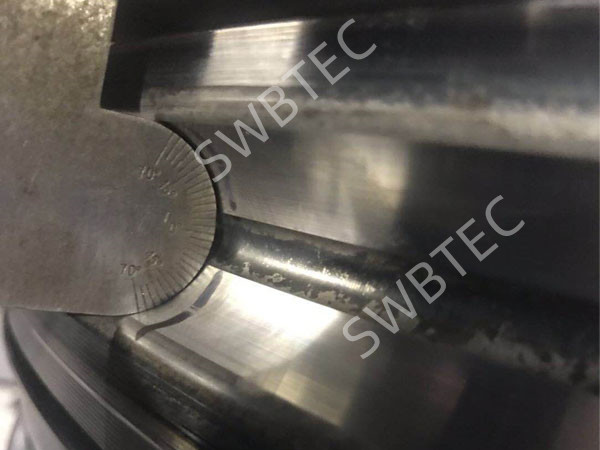

1. In order to ensure that the effective hardened layer depth of raceway quenching reaches the following table, we will regularly cut the slew bearing raceway to inspect the actual effective hardened layer depth, and will also cut the product according to customer requirements and send it to a third-party laboratory for inspecting.

Ball Size | ≤30mm | >30-40mm | >40-50mm | >50mm |

Hardening Depth | ≥3.0mm | ≥3.5mm | ≥4.0mm | ≥5.0mm |

2. We also cut the slewing bearing to check the effective hardened depth of the teeth to reach the following table and cut the raw material to check the mechanical properties including tensile strength, yield strength and elongation.

Gear Module | ≤6 | >6-12 | >12-18 | >18-25 |

Tooth Surface Depth | ≥1.2mm | ≥2.2m | ≥3.2mm | ≥4.0mm |

Tooth Root Depth | ≥0.6mm | ≥1.2mm | ≥1.5mm | ≥2.0mm |